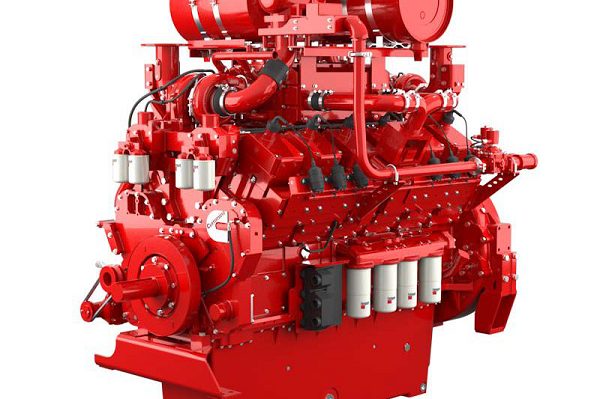

Cummins launches GTA38GCE natural gas engine

November 22, 2019

Cummins has released a new 38 L natural gas engine – the Cummins KTA38GCE – designed for midstream compression and artificial lift applications in the gas compression industry. The 12-cylinder engine, which expands on the KTA19GCE platform, offers up to 760 hp (567 kW) at 1800 rpm in continuous operation. It also shares most of the same components found in its diesel counterpart – the Cummins K38.

The new engine features the Murphy Engine Integrated Control System (EICS), which combines ignition, air/fuel ratio controls and speed-governing functions in a single engine control module (ECM), Cummins said. The EICS features smart-coil technology for reliable spark delivery, individual cylinder diagnostics and knock sensing capabilities.

Along with the engine control system, the new engine optimizes intake air and exhaust flow with Pyromet exhaust valve faces, Stellite exhaust valve seat inserts and Tribalo T400 intake valve faces and seat inserts, Cummins said. The company also developed a Holset turbocharger with two heavy-duty air clearers for this engine.

The lubrication system includes a high-capacity oil pan with combination full-flow and bypass oil filters for extended drain intervals. A two-pump, two-loop system with separate aftercooler and jacket water cooling circuits provides cooling for the engine by lowering intake manifold temperatures and increasing output.

Integrated coolant filters help eliminate corrosion. Dual direct-acting regulator assemblies help manage air/fuel control, while the speed controls use electric governors to stabilize the rpm, Cummins said. An optional input for monitoring and controlling suction or discharge pressure is also available.